Glazes are available in a variety of colors and textures. They are poured onto an unglazed ceramic piece to protect and embellish it.

The glaze has colorants as well as frits, a type of ceramic material or sand. The term “glaze” refers to a mix which is melted, quenched, and then ground to a specific mesh size.

Engobe Tile Glazing

The engobe is a fine slip that is placed between the glaze and the body. It is typically applied prior to the glaze, and is typically used as a brush decoration to cover it. The engobe is used to hide the color, conceal imperfections in the surface, for example the ones caused by impurities, such as iron, tighten and seal the porous and soft clay and to brighten glaze colors.

The recipe should be similar to the one used on the body on which it gach viglacera 30×60 will be applied. It should not have any frit added. They should also be low in flux, to ensure the opacity. Excessive flux will increase temperatures of firing and cause stress between the engobe and the sub-structure, which can test their fired marriage with cracking or shivering.

This is a common problem that is caused when you apply an engobe to dry ware, and then glaze it. The engobe should be applied when the leather-hard stage is reached. Its body-like makeup permits the creation of a bond made of plastic (fire-matching shrinkage COE, body-matching and fire-matching) to develop during drying.

Glaze is a combination of powdered materials which, when heated and dried, melts to form a smooth, glassy surface. Glazes are applied by spraying or dipping into. They are made to bind with the clay surface in a zone of adherence called the interface between clay and glaze. When dried, the slurry particles draw closer and shrink. the more vitreous bodies shrinking faster than other.

Digital Inkjet Printing Tiles

Inkjet printing is a common technology that is used in both home and office printers to produce photo-quality images. Ceramic tile manufacturers are now employing the same process to create patterns and designs that add beauty to interior spaces.

This process utilizes a special ceramic ink that can withstand the high temperatures of firing ceramics. The designs printed on the paper remain vibrant and vivid when the ceramics are glazed and fired. This unique process enables manufacturers to create tiles that look similar to natural materials. These are wood-look tiles and colours inspired by stone, as well as abstract designs.

Ceramic digital printing is also an excellent option for producers who want to boost productivity and lower costs of production. Digital printing machines eliminate the need for expensive and complicated equipment like screens and rollers. This is why they are a more cost-effective alternative to traditional methods. Additionally the digital printing method can produce smaller runs as compared to custom screen or rotocolor printing, which reduces the quantity of storage and inventory required.

LOPO utilizes a leading Italian digital tile printing machine that creates innovative new designs for the terracotta. The LOPO 3D Inkjet Printing Tile Series, which combines the highest-quality ceramic ink for digital printing with the latest printers to create extremely creative patterns, replicates natural textures, such as marble and wood.

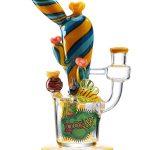

Crystalline Glaze Tiles

Crystalline glazes are used to add decoration to ceramic objects. The glaze surface is given an unique crystal structure mixing frits, pigments and a low firing temperature with a slow cooling rate. Crystalline structures are well-liked in contemporary designs due to their distinctive appearance and long-lasting. This technique is typically used on high-end floor tiles, however it can also be applied to other kinds of pottery as well.

Four different glaze designs for porcelain stoneware tiles were examined for their tribological properties by means of analytical tests (thermal analysis, Vickers hardness) and technological ones (surface abrasion test). The glazes used for the research were commercially produced produced by Colorobbia Italia S.p.A., Fiorano Modenese Modena, Italy, and were made according to the specific recipes as described in Table 1.

To conduct the tests on surface abrasion Unfired 30x30cm tiles were coated with airless application with engobe glazes and slurries that have densities of 1470 kg/m3. Digitally printed patterns were applied to the engobe. The slurries are single-fired with a temperature of 30 degrees Celsius per minute with a maximum temperature of 1205 degC. The resulting disks were dry-cleaned then ground to a size that was less than 0.063mm, and analyzed using X-ray diffractography (XRD), on an Empyrean Series III from Malvern Panalytical Ltd. located in Malvern, UK.

Lappato Finish Tiles

The lappato finishing technique represents a refined middle way between polished and matte tile finishes. It strikes an equilibrium that gives visual depth while also preserving the texture of the surface. The technique uses selective abrasions to polish tiles, leaving sections with a shiny sheen. other areas remain matte giving a distinctive appearance that reflects light, but does not eliminate texture. This unique blend of shine and texture adds elegance to interiors but requires more attention.

The quality of diamond lappato abrasives is essential to the success of this finishing technique. Diamond abrasives that are of the highest quality are more durable than ceramic tiles (typically 10 on the Mohs Scale), allowing them to eliminate materials with greater efficiency and less wear. In addition water lubrication helps control the temperature and avoid overheating.

It is crucial to think about the size of the diamond particles when selecting the abrasives. The larger diamond particles give an appearance that is more rough and the diamonds with finer particles provide a smoother finish. The type of adhesive used to join the diamonds to abrasives is also a major factor in achieving a consistent finish. Metal-bonded diamonds are stronger and provide better performance than resin-bonded diamonds.

After the abrasive treatment it is essential to thoroughly wash the lappato tiles with an acid-neutral cleaner. This will eliminate any polishing residues and make them ready to grout. A simple test of water break can also be used to determine consistency and ensure the abrasive treatment is producing an appearance that is uniform. Sprinkle a tiny amount of clean water on the surface. The water should spread evenly and should not crack, proving that the tile has been treated uniformly.