Industrial Electronics Repair Quality Control is a key component in any manufacturing. Quality control systems can distinguish quality products from poor ones and aids workers to correct their mistakes.

If, for instance, an oily residue appears to be caused by trace of solder on your product’s trace It could be noticed by the QC inspecting team of the customer. In this case the product may need to rework the product.

Importance

Quality control is a crucial procedure that guarantees the consistency and precision across all product lines. It includes inspection, testing and documenting to find flaws and deviations from standards. It also includes corrective measures to address any issues.

For companies producing electronics Quality control is crucial to minimize costs and losses, reduce liabilities, and ensure a positive reputation. This includes ensuring that deadlines are met as well as delivering the goods promised and discovering any potential flaws before they impact negatively the process of production.

It’s important to achieve this because globalization has forced companies to expand their production. Quality products and services will help to build brand recognition improve efficiency, and build an enduring customers base. Businesses will be able to grow their market and compete globally. An inadequate quality control system could result in a myriad of issues. These include resource waste, errors caused by human error, or poor specification for the product.

Longevity and Reliability

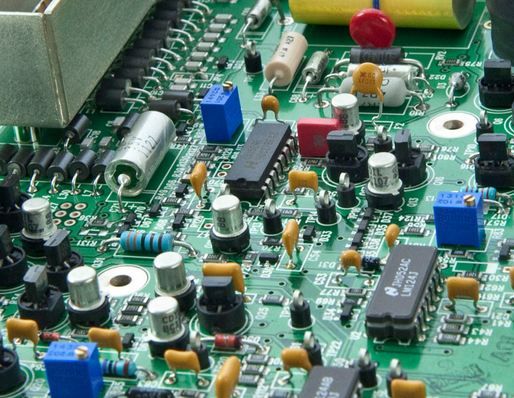

By automating and providing accuracy, industrial electronic devices provide a great deal of benefit to businesses on the factory floor. But these electronics are also susceptible to failures, similar to any other component of equipment or device. It is crucial to fix and maintain them through routine maintenance to prevent the damage.

It is important to repair and maintain electronics to prevent planned obsolescence. This is the reason why many producers focus on reliability and durability of their products. It’s crucial to not confuse longevity with reliability, because this can be misinterpreted with MTBF values (Mean Time Between Faults) of components.

Additionally improving the repairability as well as the resales of electronic devices will help create a brand innovative business models like devices as services, upgrade plans and sales of parts. This could help in the development of circular supply chain.

Standards Conformity

To guarantee the high-quality and safety of goods there are a variety of laws put in place. Some of these regulations could be costly or time-consuming. However, they are essential for the security of the consumers and businesses who utilize the products.

The management of risk is an essential aspect of the quality control process. It helps companies discover potential issues then rectify them to prevent damage to production processes. The company also works to keep costs to a minimum while keeping deadlines.

If a company is in the field of electronics who wants to make it in the world market, it’s crucial that they adhere to the industry standard. There are different standards depending the type of product you have. In the case of example, if your company manufactures electronic equipment that operate on electricity the device, then your business must comply the European Union (EAEU) Regulation 048/2019. The devices must undergo an examination and be awarded quality certificates.

Cost-Efficiency

Repairs that are quality controlled isn’t just important but also an efficient way to cut costs. This process can help sua bien tan cut down on waste and unneeded losses. It also ensures that all the processes and components function properly and running at maximum efficiency.

Here are the essential elements of quality control for repairs made by electronic devices:

This will prevent errors for example, placing the component on the wrong spot. This can also be used to find missing parts.

Resistors are replaced. These passive components, which resist electric current, and can serve as a barrier to power, are found throughout circuits and are often the result of damaged electronic components. They are usually replaced when they fail, and a repair facility will be sure that they have the same design as the originals.

Good repair centers will provide complimentary equipment evaluations and quotations free of bench costs. Repair centers offer warranties that cover both parts and labor.